SA Stack Actuators

150V Piezoelectric Stack Actuators

Specifications:

| Prod. Model | Range +/-10% | Lgth (1) | Cross Sect | Cap. +/-20% | Mass | Block Force | Stiff. | Res. Freq. |

|---|---|---|---|---|---|---|---|---|

| um | mm | mm | uF | g | N | N/um | kHz | |

| SA030305 | 5.6 | 5 | 3x3 | 0.140 | 0.53 | 330 | 80 | 300 |

| SA030310 | 14 | 10 | 3x3 | 0.300 | 1.1 | 330 | 33 | 150 |

| SA030318 | 25 | 18 | 3x3 | 0.500 | 2.0 | 330 | 18 | 83 |

| SA050510 | 14 | 10 | 5x5 | 0.630 | 2.0 | 900 | 108 | 150 |

| SA050520 | 31 | 20 | 5x5 | 1.8 | 4.0 | 900 | 41 | 74 |

| SA050536 | 56 | 36 | 5x5 | 4.3 | 7.1 | 900 | 28 | 42 |

| SA070718 | 28 | 18 | 7x7 | 4.1 | 7.0 | 1800 | 120 | 83 |

| SA070742 | 70 | 42 | 7x7 | 10 | 15 | 1800 | 51 | 36 |

(1) Length tolerance is +/-0.05 mm

Features

The PiezoDrive SA stack actuators are high-performance piezoelectric stack actuators with a UV cured epoxy coating for improved mechanical and humidity protection. The SA actuators are matched to the range of PiezoDrive amplifiers and driver modules. Applications include: Nanopositioning, Microscopy, Precision Machining, Vibration Control, Hydraulic Pumps, Valves, and Optics.

Calculate Power Bandwidth

Calculate Power Bandwidth

External Insulation

The SA actuators can be supplied with a thermoplastic sleeve which provides additional mechanical protection and insulates the electrode contacts. For this option, add “-B” to the part number, e.g., “SA050510-B”. Minimum order quantities and lead-times apply, except for the SA050510-B and SA050536-B which are available from stock.

Mounting

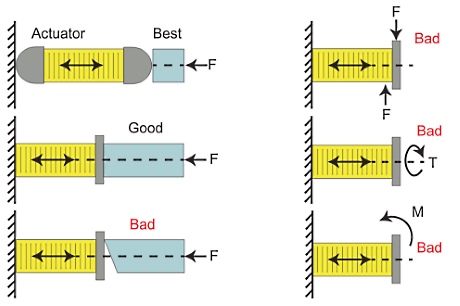

Stack actuators should not be exposed to significant tensile loads, unequally distributed loads, off-axis loads, bending moments, or torque. To reduce mounting errors, a ceramic or stainless steel ball end can be used to interface the stack actuator to the load. Flexural mechanisms are also recommended.

Suitable adhesives for low temperature operation include cyanoacrylate, e.g. superglue gel, and general-purpose two-part epoxies, e.g. Loctite 3430. In applications where heat dissipation or operation at elevated temperature is required, Loctite 9466 is recommended.

The maximum recommended tensile load is 10% of the blocking force. In applications that require bi-directional forces or high-speed motion, a preload force is recommended with a magnitude greater than the maximum tensile load. This guarantees that the actuator is always in compression. The maximum recommended preload is 50% of the blocking force.

Ball Ends

PiezoDrive stack actuators can be supplied with ceramic ball ends to improve the load distribution, simplify the mounting, and reduce bending moments during service. One or two ball ends can be specified by adding one of the following suffixes to the order code: -TBE (Top Ball End), -BBE (Bottom Ball End), or -2BE (Both Ball Ends). E.g. SA070718-2BE.

| Actuator Width | Ball End Diameter | Additional Length |

|---|---|---|

| 3 mm | 3 mm | 3 mm |

| 5 mm | 5 mm | 5 mm |

| 7 mm | 6.5 mm | 6.5 mm |

Range

The range is specified for an applied voltage of -30V to +150V. If the input voltage is unipolar (0V to +150V) the specified range is reduced by a factor of 0.75. When a stack actuator is driving a stiff spring, the range is reduced by the factor

where kp is the actuator stiffness and kL is the load stiffness.

The travel range can also be reduced by restraining the end plates, e.g. by bonding the actuator to a stiff base. This effect is most significant in actuators that have a length less than twice the width.

Capacitance

The actuator capacitance is the small-signal capacitance measured at room temperature. Due to hysteresis, the effective capacitance increases with applied voltage. When operating at full range, the effective capacitance is approximately twice the small-signal capacitance. The capacitance also increases with temperature. A temperature increase of approximately 50 degrees C will double the effective capacitance.

Thermal

Piezoelectric actuators dissipate heat when driven at full range with a high frequency. PiezoDrive actuators can be operated continuously at temperatures up to 85 degrees C. Continuous operation beyond this temperature may damage the actuator.

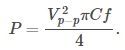

The dissipated heat is approximately 10% of the applied electrical power. For a sine-wave, the applied electrical power is:

Electrical Current Requirements

Calculate Power Bandwidth

Calculate Power Bandwidth

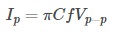

The required current is I=C dV/dt where I is the current, C is the effective capacitance, and dV/dt is the voltage rate of change. For a sine-wave, the required peak current is equal to:

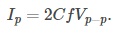

where Vp-p is the peak-to-peak voltage. For a triangle wave, the required peak current is equal to:

Recommended Drivers

| Amplifier | Application |

|---|---|

| PDm200B | General purpose, low cost |

| MX200 | High Current, Low noise, low cost |

| PDu150 | Ultra-low noise |

| PD200 | High speed, low noise |

| PX200 | High current, low noise |

Connecting Wires

Standard connecting wires are listed below. Other lengths are available on request. Red identifies the positive terminal.

- SA0303 Series: 100mm Length, Solid PTFE Insulation, 0.5mm Outside Diameter, 0.050mm Conductor (AWG30)

- SA0505 Series: 100mm Length, Solid PTFE Insulation, 0.64mm Outside Diameter, 0.106mm Conductor (AWG27)

- SA0707 Series: 100mm Length, Solid PTFE Insulation, 0.64mm Outside Diameter, 0.106mm Conductor (AWG27)

The SA Actuators are supplied with a UV cured epoxy coating, with or without a thermoplastic sleeve. Both coatings and the wiring insulation meet the outgassing requirements for NASA SP-R-0022A.

Options/OEM Customization

- Ceramic ball ends (Order suffix - 1BE or 2BE)

- Custom range and dimensions

- Custom wiring arrangement/connectors

- Preload or mechanical amplifier mechanisms

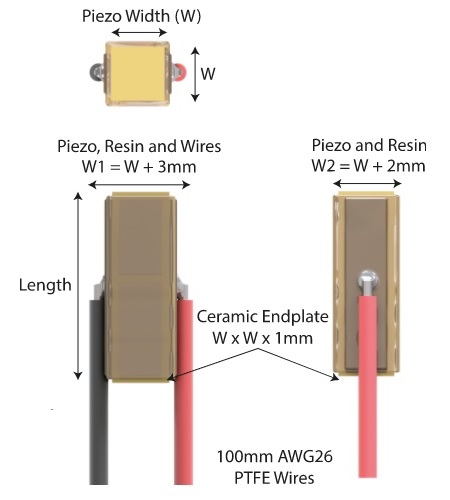

Dimensions

The total stack dimensions are based on the width and length of the ceramic listed in the specifications. The length specification includes the piezoelectric stack and two 1-mm thick ceramic end plates. The length tolerance is +/- 0.05 mm.

Piezoelectric Properties

The piezoelectric material is similar to PZT-5H and Navy Type VI.

| Property | Symbol | Value | Unit |

|---|---|---|---|

| Piezoelectric constants | d33 | 600 | 10-12 m/V |

| d31 | -270 | 10-12 m/V | |

| g33 | 19.4 | 10-3 Vm/N | |

| g31 | -9.2 | 10-3 Vm/N | |

| Electro-mechanical coupling coefficients | Kp | 0.65 | NA |

| Kt | 0.37 | NA | |

| K31 | 0.38 | NA | |

| Frequency constant | Np | 1980 | Hz-m |

| Nt | 1950 | Hz-m | |

| N31 | 1450 | Hz-m | |

| Elastic constant | Y33 | 5.3 | 1010 N/m2 |

| Y11 | 7.2 | 1010 N/m2 | |

| Q Factor | Qm | 80 | NA |

| Dielectric constant | e33/e0 | 3500 | @1 kHz |

| Dissapation factor | tan δ | 2.5 | % @ 1 kHz |

| Curie Temperature | Tc | 220 | C |

| Density | ρ | 7.8 | g/cm3 |

| Density | α | 3.5 | ppm/C |